HOW TO MAKE "VASE"

|

Act.1 Soil mining The soil mined contains mainly clay, kaolin, feldspar, silica stone, porcelain stone, talc, caustic lime, etc. Stone shaped raw materials are crashed roughly by grinder. |

| ↓ | |

|

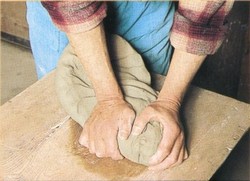

Act.2 Soil kneading First, the soil laid out for a certain period of time so that the hardness and moisture is spread evenly. Then, the soil is kneaded by slow rotation in order to release the air in the soil. As the kneading shapes the soil, the soil begins to looks like the petals of chrysanthemums, and thus, it is called “Chrysanthemum kneading”. |

| ↓ |

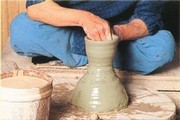

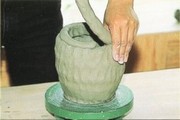

| Act.3 Molding | ||

|

|

|

| The method used to here creates the form of the clay. Using the centrifugal force of the wheel, the soil on the wheel is pulled up using both hands, while the fingers and palms shapes the clay. it by your fingers and palms. Delicate rotation with finger works. | This is the method of making the soil into a string shape, which is then coiled into a certain shape. In order to prevent the outer edges from widening, the string must be coiled from the left hand side by twisting it to the opposite side. | This is the method of shaping the product by using a half dried “tatara” (board shaped kneaded soil.) This is a simple method, but the important to be careful of the “tatara’s” degree of dryness. |

| ↓ | |

|

Act.4 Drying After shaping and processing scrap etc., dry the products slowly with or without sun before baking without glaze. Drying time depends on size and thickness of the products. |

| ↓ | |

|

Act.5 Baking without glazing Bake the shaped and dried products in an oven with 700-800℃(1300-1500 degree F). This process makes the products stronger, increases the water absorption, and helps the product become much easier for glazing. |

| ↓ | |

|

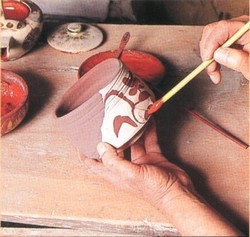

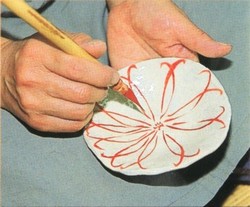

Act.6 Shita-e-thuke (Initial drawing before glazing) The word “shita-e-thuke” means drawing before glazing. In other words, it means that the designs are drawn under the glaze. You can draw designs with your favorite colors using a drawing brush. |

| ↓ | |

|

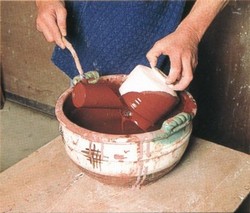

Act.7 Glazing Glazing is to cover glazing agent over baked products of the previous stage in order to decorate and make them strong. There are several methods of glazing, such as “subukake,” “hishaku-gake,” “spray-gake,” etc. |

| ↓ | |

|

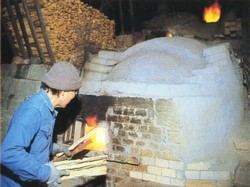

Act.8 Honyaki(real baking) After glazing, bake in a oven with high temperature. Place the products carefully in a oven, making the whole oven with even density and bake. There are several types of oven, such as ascending oven, gas oven, electric oven, etc. |

| ↓ | |

|

Act.9 Ue-etsuke (Drawing upon glazing) “Ue-etsuke” is the method of drawing designs after glazing and “hon-yaki”(real baking). Using paint specially made for “Ue-etsuke,” you can draw delicate lines during this stage. |

| ↓ | |

| Act.10 Ue-e-shousei After the “Ue-etsuke,” the products are baked again in a low temperature oven with 700-800℃(1300-1500 degree F). |

|

| ↓ | |

|

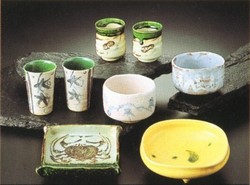

Act.11 Completion After “honyaki”(real baking), do finishing file and they are done. |